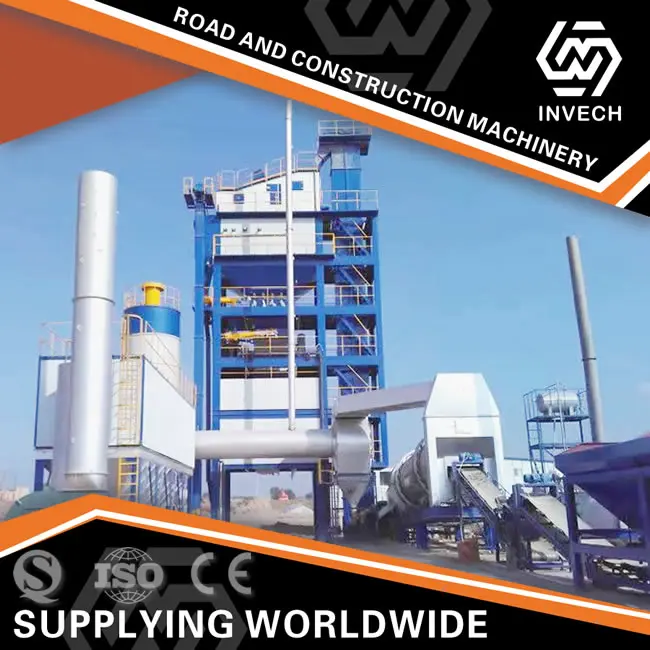

Asphalt mixing plant

Model No.︰IVLB-1500

Brand Name︰INVECH

Country of Origin︰China

Unit Price︰US $ 150000 / pc

Minimum Order︰1 pc

Product Description

High Quality Asphalt Mixing Plant IVLB1500 for Road Construction Engineering

IVLB Series mobile asphalt mixing plant inherits the advantages of IV series asphalt batch mixing plant, and adds new elements including: containerized size, modular design and trailer and mobile chassis which make it possible for container transportation, fast mobilization and relocation.

IVLB Asphalt Plant is designed for small and medium-sized pavement project which need frequent relocation.

Complete plant can be dismantled and reinstalled in 5 days (not including the transportation period).

Parameter:

|

model |

IVLB1500 asphalt mixing plant H.S code: 84743200 |

|

type |

Forced hot stirring |

|

output |

120 ton/hour |

|

mortar mixer capacity |

1500KG/batch |

|

Fuel (diesel engine) |

Consumption: 5.5-7.5kg (per ton of finished asphalt concrete) |

|

weighing accuracy |

Hot aggregate: ±0.5%; Asphalt: + / - 0.3%; Kuangfen, plus or minus 0.2% |

|

Finished material temperature |

130℃-165℃ |

|

air contamination |

≤20mg/Nm³ |

|

Noise |

≤70db(A) |

|

Operating |

Automatic Mode, Semi-automatic Mode, the manual mode can be switched. |

|

Installed power |

300 kw |

|

Rated Voltage |

220V/380V-50Hz |

|

occupied area |

43m*32m*18m |

|

Weight |

98t |

|

random file |

General installation drawing Foundation drawing circuit drawing Instruction manual Product certificate |

|

Certificate |

CE EAC |

Main Features:

Drying System

1. Adopts four sets of famous powerful direct-connected gear motors to drive the drying drum;

2. Optimized blades make the drying process more balance with higher heat utilization rate;

3. Drying drum is covered by thermal insulation material and stainless steel skin to avoid heat loss;

4. Well calculated and carefully heat-treated drying drum, world-class bearings have a long service life and stable performance.

Dust Collecting System

1. Double dust collecting system, European emission standards;

2. Pulsating dust removal method, energy saving and efficient;

3. Durable key components;

4. Safety protection, intelligent inspection.

Vibrating Screen

1. Sturdy and durable, high intensity and remarkable screening effect;

2. Screen mesh easy to maintain and replace, time-saving;

3. Frequency and amplitude perfectly matched, over 95% grading precision, competent to any severe working situation, high-temperature resistance and excellent productivity;

4. Best design to guarantee the best screening result.

a. Adopts self-synchronizing driving technology, maintenance-free and environmental;

b. Patent enhanced drivable bridge structure design, tough and protective for screening components;

c. Famous vibrating motor.

Mixing System

1. Simulating optimization of material mixing movement speed;

2. Ensures each batch is totally and equally mixed with 25% mixing efficiency enhancement and 20% energy consumption reduction;

3. High productivity double-shaft mixer

Payment Terms︰ T/T

Product Image